SECTORS

Waste

Lithium-ion batteries pose a unique and growing challenge for the UK waste sector. They are unpredictable, hazardous and increasingly common in everyday waste streams.

Recyclus provides the specialised infrastructure and expertise needed to safely manage and recycle lithium-ion batteries, enabling operators to protect sites, staff, and communities while advancing circular-economy goals.

Helping the waste sector manage the UK’s fastest-growing hazard

The waste and recycling industry is facing a surge in lithium-ion batteries entering mixed waste, WEEE, municipal recycling, and commercial waste streams. These batteries — often hidden inside everyday items — have become one of the leading causes of fires, contamination incidents, and operational disruption across the sector.

Key challenges the waste industry now faces:

-

Lithium-ion batteries are responsible for a rising number of fires in MRFs, HWRCs, transfer stations, and waste bays

-

Hidden batteries are entering waste streams through toys, tools, vapes, electronics, and textiles

-

Growing regulatory pressure to safely segregate and recycle lithium-ion batteries

-

A need for secure, compliant routes for end-of-life batteries across all waste categories

-

Limited UK-wide infrastructure capable of recycling lithium-ion at industrial scale

Recyclus Group provides a specialist, UK-based solution that integrates seamlessly with your waste operations — delivering safe collection, handling, and recycling of lithium-ion batteries at scale.

Our Waste Sector Services

Here’s how we support you end-to-end:

Safe Collection, Storage & Transport

Recyclus supports waste operators, local authorities and recycling companies with:

-

ADR-compliant transport for lithium-ion batteries and mixed battery loads

-

Fire-safe UNP911- certified “LiBox” storage containers for HWRC sites, MRFs, WEEE facilities and transfer stations

-

Guidance on segregation and safe storage of high-risk Li-ion battery types

-

Collection schedules designed to support both local and national operators

-

Full chain-of-custody documentation for compliance and audit readiness

Our infrastructure ensures batteries are removed from waste streams before they become a fire or contamination risk.

Sorting, Stabilisation & Pre-Treatment

Lithium-ion batteries arrive in the waste stream in unpredictable and unsafe conditions. Recyclus provides:

-

Sorting of mixed Li-ion battery and WEEE loads into the correct categories for recycling

-

Stabilisation of swollen, punctured, water-damaged or fire-compromised cells

-

Depowering and neutralisation processes to eliminate thermal risk (where necessary)

-

Handling of cross-contaminated loads from MRFs and WEEE facilities

-

Safe processing of high-volume waste streams from local authorities and commercial waste contracts

This reduces risk on-site and ensures full compliance with UK waste handling regulations.

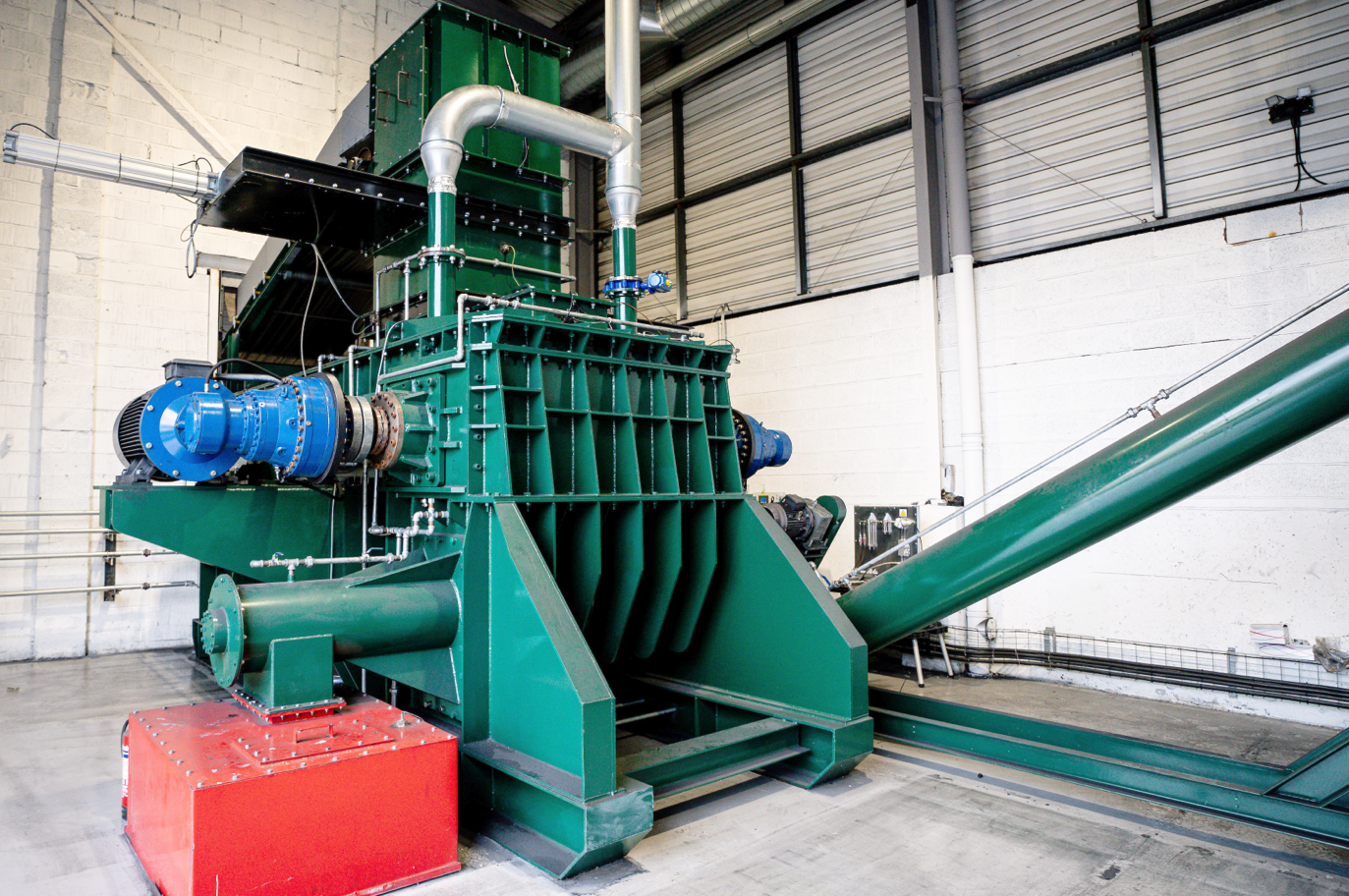

Industrial-Scale Lithium-Ion Recycling

Recyclus operates one of the UK’s first industrial-scale lithium-ion recycling facilities, processing batteries from:

-

MRFs and sorting lines

-

HWRC sites and local authority waste

-

WEEE processors and collection depots

-

Commercial waste streams

-

Mixed household and municipal waste collections

Our process recovers:

-

Black mass containing lithium, cobalt, nickel, and manganese

-

Aluminium and copper

-

Plastics and other material fractions

Full certificates of recycling and environmental reporting are provided for all loads.

Fire Risk Reduction & Waste-Site Safety Consultancy

Lithium-ion batteries represent one of the greatest fire risks within the waste sector. Recyclus supports operators with:

-

Best-practice segregation methods for HWRCs, MRFs, and bulking areas

-

Guidance on safe Li-ion battery storage, container layout, and emergency isolation zones

-

Guidance on lithium-ion hazards and handling

-

Operational procedures for dealing with damaged or burning batteries

-

Compliance support for UK Batteries Regulations and WEEE directives

These services significantly reduce the likelihood of fires, injuries, and operational shutdowns.

How It Works

Waste Process Flow

1. Arrange Collection

Arrange Collection

2. Initial Inspection

Initial Inspection

3. Containment

Containment

4. Safe Dismantling

Safe Dismantling

5. Recycling & Recovery

Recycling & Recovery

6. Certifications & Reporting

Certifications & Reporting

5. Recycling & Recovery

Recycling & Recovery

6. Certifications & Reporting

Certifications & Reporting

Strategic Benefits for Waste Partners

Significant Reduction in Fire Risk

Significant reduction in fire risk, protecting staff, assets, and insurance profiles

Compliance Assurance

Full compliance with UK Batteries Regulations and WEEE requirements

Secure UK-Based Recycling

Secure UK-based recycling, avoiding costly export routes

Scalable Capacity

Scalable capacity suitable for both local operators and national waste networks

Secure & Confidential Battery Handling for Sensitive Products

Recyclus provides specialised handling for confidential waste streams and next-generation product trials, ensuring security, discretion and full compliance at every stage.

Our facility is equipped to process:

-

Batteries from confiscated or restricted items, received through approved waste partners

-

Prototype, pre-production and next-generation devices from automotive, robotics, electronics and industrial sectors

-

Development batteries used in R&D labs, engineering teams and controlled testing programmes

-

Sensitive equipment requiring secure destruction, full audit trails and verified recycling outcomes

All confidential materials are managed under secure processes with:

-

Controlled access zones

-

Full chain-of-custody tracking

-

Secure destruction certificates

-

Non-disclosure aligned handling for sensitive technologies

This ensures high-risk or confidential battery waste — whether from law-enforcement seizures or cutting-edge engineering trials — is processed safely, discreetly and in full compliance with UK regulation.

Why Recyclus Group?

- Specialist handling of damaged, degraded, or fire-affected energy-storage units

- Complete end-to-end handling: collection, stabilisation, and recycling

- Robust compliance, documentation, and traceability

-

-

We are the UK’s first industrial-scale lithium-ion battery recycler.

-

Our Wolverhampton facility is fully operational and processing large volumes of Li-ion batteries.

-

Proven capability with large, mixed, and fire-damaged lithium-ion battery loads

Find Your Bespoke Solution

Call Us

+44 (0) 1902 287561

Email Us

HQ Address

Lincoln Street,

Wolverhampton,

WV10 0DX