Lithium-Ion Battery Recycling

Industrial-Scale Recycling at LiBatt, Wolverhampton

Lithium-Ion Battery Recycling

Industrial-Scale Recycling at LiBatt, Wolverhampton

Lithium-Ion Battery Recycling

Industrial-Scale Recycling at LiBatt, Wolverhampton

Lithium-Ion Battery Recycling at LiBatt

LiBatt, a subsidiary of Recyclus Group, is home to our state-of-the-art lithium-ion (Li-ion) battery recycling facility in Wolverhampton. Designed entirely in-house, the LiBatt plant is currently the UK’s only industrial-scale Li-ion recycling facility and is capable of recycling lithium-ion batteries of any shape, size, or chemistry, including burnt or damaged materials.

Driven by regulations promoting the use of recycled materials in new batteries, LiBatt supports a shift toward a cradle-to-cradle solution. Instead of ending up in landfills or incinerators, end-of-life batteries are processed to recover valuable critical materials, typically lithium, nickel, and cobalt. These recovered materials are reintroduced into the production cycle, fostering a sustainable system for battery manufacturing and advancing the circular economy.

We issue end-of-life battery certificates to our clients, providing reassurance that all batteries have been safely and responsibly recycled.

Key Details of Plant

Fully automates shredding, separation and waste fraction bagging.

Automotive batteries discharged and dismantled.

Accepts 5+ Li-ion battery chemistries, in any condition, including damaged or burnt units.

Shreds dry under an inert atmosphere of Nitrogen.

Recovers electrolyte through a vacuum dryer.

Screens & recovers black mass: 125 to 500 µm.

Separates & recovers ferrous metals, non-ferrous metals, and polymers.

Produces minimal gas & particulate emissions, with low energy consumption.

Monitors remotely with data feedback systems.

Operates without hydro or pyro pre-treatment.

Types of Lithium Batteries That We Recycle

High-Voltage Packs

Our skilled technicians are fully equipped to safely test, discharge, and dismantle all types of high-voltage battery packs.

Battery Modules

No matter the application or condition, we offer sustainable solutions for all types of battery modules.

Battery Cells

We are equipped to manage all types of lithium battery cells, regardless of their form factor, size, or chemistry.

Burnt Material & Production Scrap

We offer a sustainable recycling solution for everything from burnt battery materials to anode and cathode materials generated across the production line.

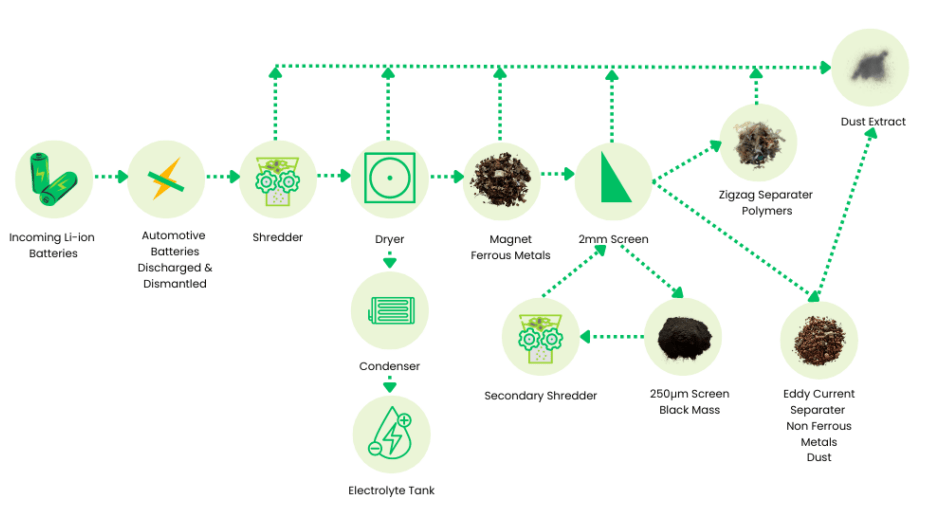

Our Process

1. Battery Discharging

We safely discharge lithium-ion batteries to remove any remaining energy before processing. This is a critical step to prevent thermal runaway, reduce fire risks and ensure safe handling during dismantling and recycling.

2. Battery Dismantling

We can dismantle any battery pack, from units weighing under 100kg to those exceeding 600kg. Our advanced processes allow us to efficiently separate battery components, recovering valuable materials while ensuring hazardous elements are handled safely and in compliance with regulations.

3. Mechanical Separation and Shredding

Our advanced mechanical separation and shredding process is fully automated, ensuring the safe, efficient, and environmentally responsible recycling of lithium-ion batteries. Operating under an inert nitrogen atmosphere, the system mitigates oxidation risks and enhances safety. Batteries are shredded in a dry state, while a vacuum dryer effectively captures and recovers electrolyte for further processing.

Precision screening technology extracts black mass particles ranging from 125 to 500 µm, while sophisticated separation systems recover ferrous metals, non-ferrous metals, and polymers with high efficiency. Designed for minimal environmental impact, the process generates low gas and particulate emissions and operates with reduced energy consumption.

Continuous remote monitoring with real-time data feedback optimises performance and ensures operational reliability. Unlike conventional methods, our approach eliminates the need for hydro or pyro pre-treatment, offering a more sustainable and efficient solution for battery recycling

As featured on:

Recovery and Extraction of Critical Materials

At our LiBatt plant, we sustainably and efficiently recover a diverse range of critical minerals from end-of-life lithium batteries. Our advanced processing facility produces high-quality “Black Mass,” typically comprising lithium, nickel, and cobalt.

Case Studies

Halfords

Powervault

Future Projects and Research

Recyclus Group, in partnership with the University of Birmingham and partially funded by Innovate UK, is developing a mobile battery recycling system capable of safely processing all types of lithium-ion batteries.

Leading the initiative, Recyclus Group is designing and constructing a compact prototype recycling truck, leveraging the proven LiBatt plant technology from our Wolverhampton facility.

We collaborate with diverse industries and sectors.

AUTOMOTIVE

Recyclus collaborates with automobile manufacturers and leaders in electric vehicle technology to recycle lithium-ion batteries and other automobile batteries ethically and efficiently.

PORTABLES

Recyclus can sustainably recycle all types of portable lithium-ion batteries from the WEEE sector. Our advanced recycling processes are designed to manage end-of-life batteries from a diverse array of devices, including mobile phones, laptops, tablets, power tools, vapes, and other electronic gadgets.

HEALTHCARE

The NHS and various healthcare organisations throughout the UK and Europe depend on Li-ion batteries daily for devices such as critical care equipment, pacemakers, ventilators, defibrillators, and more.

ROBOTICS

Lithium-ion batteries play a pivotal role in enhancing operational efficiency and endurance of robotic systems deployed by industry leaders. We are committed to providing a sustainable end-of-life solution for a diverse range of lithium-ion batteries crucial to the robotics industry.

E-MOBILITY

Recyclus’ lithium-ion battery recycling service can be customised for the dynamic and evolving e-mobility sector. We are dedicated to offering a comprehensive end-of-life solution for a wide variety of lithium-ion batteries essential to e-mobility.

WASTE + RECYCLING

In the waste and recycling sector, Recyclus actively partners with recyclers, waste management companies, environmental consultants, scrap dealerships, facility management companies, refiners, and other stakeholders.

ENERGY / UTILITY

At Recyclus, we collaborate with various organisations in the energy and utility sector to sustainably recycle all types of Li-ion batteries. Whether for BESS grid storage applications or electric and gas meters, we are fully equipped to meet the sector’s needs.

DEFENCE / AEROSPACE

Defence and aerospace companies use lithium-ion batteries because of their high energy density and reliability in extreme conditions. We are focused on providing sustainable end-of-life solutions for lithium-ion batteries that play a vital role in the defence and aerospace sectors.

Certifications

Find Your Bespoke Solution.

To schedule a collection or get more information about our battery recycling services, complete the form and a team member will contact you shortly.