SECTORS

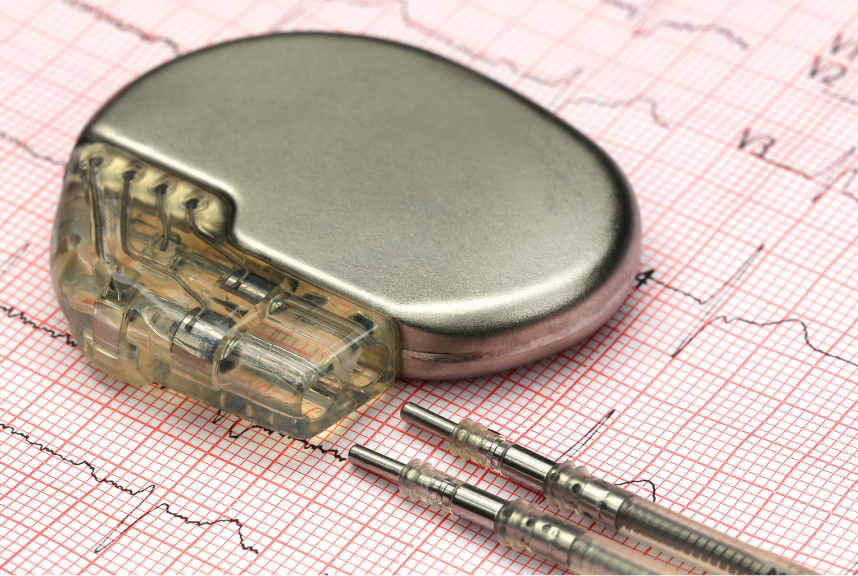

Healthcare

As healthcare modernises, the number of lithium-ion powered devices in clinical use will continue to grow. Without proper end-of-life pathways, risks escalate — from fire hazards and compliance breaches to unnecessary environmental impact.

Recyclus provides the secure, specialist, and scalable recycling infrastructure needed to manage these batteries responsibly across the healthcare sector.

Keeping Healthcare Powered — and Safe

Modern healthcare relies on thousands of lithium-ion powered devices. From portable diagnostic tools and monitors to mobility systems, handheld equipment and digital health technologies, lithium-ion batteries are now embedded across nearly every department.

But as healthcare digitises, the sector faces new challenges:

-

Growing volumes of end-of-life lithium-ion batteries from medical devices, mobility aids and equipment

-

Increased fire-risk associated with swollen, damaged or ageing batteries

-

Compliance requirements around the safe disposal of Li-ion batteries from electronic medical equipment

-

A need for secure, traceable and auditable recycling processes

-

Pressure to meet sustainability and Net Zero commitments across NHS and private healthcare estates

Recyclus Group provides a specialist, secure and fully compliant solution for end-to-end lithium-ion battery management — designed specifically for healthcare environments.

Our Healthcare Sector Services

Here’s how we support you end-to-end:

Safe Collection, Storage & Transport

We support hospitals, care homes, clinics, laboratories, medical distributors, and healthcare estates with:

-

ADR-compliant transport for lithium-ion batteries and medical-device packs

-

Our fire-safe, UNP911- certified “LiBox” containers meet Packing Group I and ADR P911 regulations and can be used for wards, workshops, stores, and by biomedical engineering teams

-

Scheduled collections to suit hospital operations

-

Segregation guidance for medical devices containing embedded lithium-ion cells

-

Full chain-of-custody documentation for compliance, audit, and governance

All collections follow strict health, safety, and confidentiality standards required across healthcare settings.

Sorting, Stabilisation & Pre-Treatment

Healthcare devices often contain embedded or sealed battery systems requiring skilled dismantling.

Recyclus provides:

-

Safe extraction of Li-ion batteries

-

Sorting into correct chemistries, hazard classes, and disposal categories

-

Stabilisation of swollen, leaking, or damaged healthcare battery packs

-

Pre-treatment and depowering to remove fire and contamination risk

-

Controlled handling for bulk disposals, equipment upgrades, or estate refurbishments

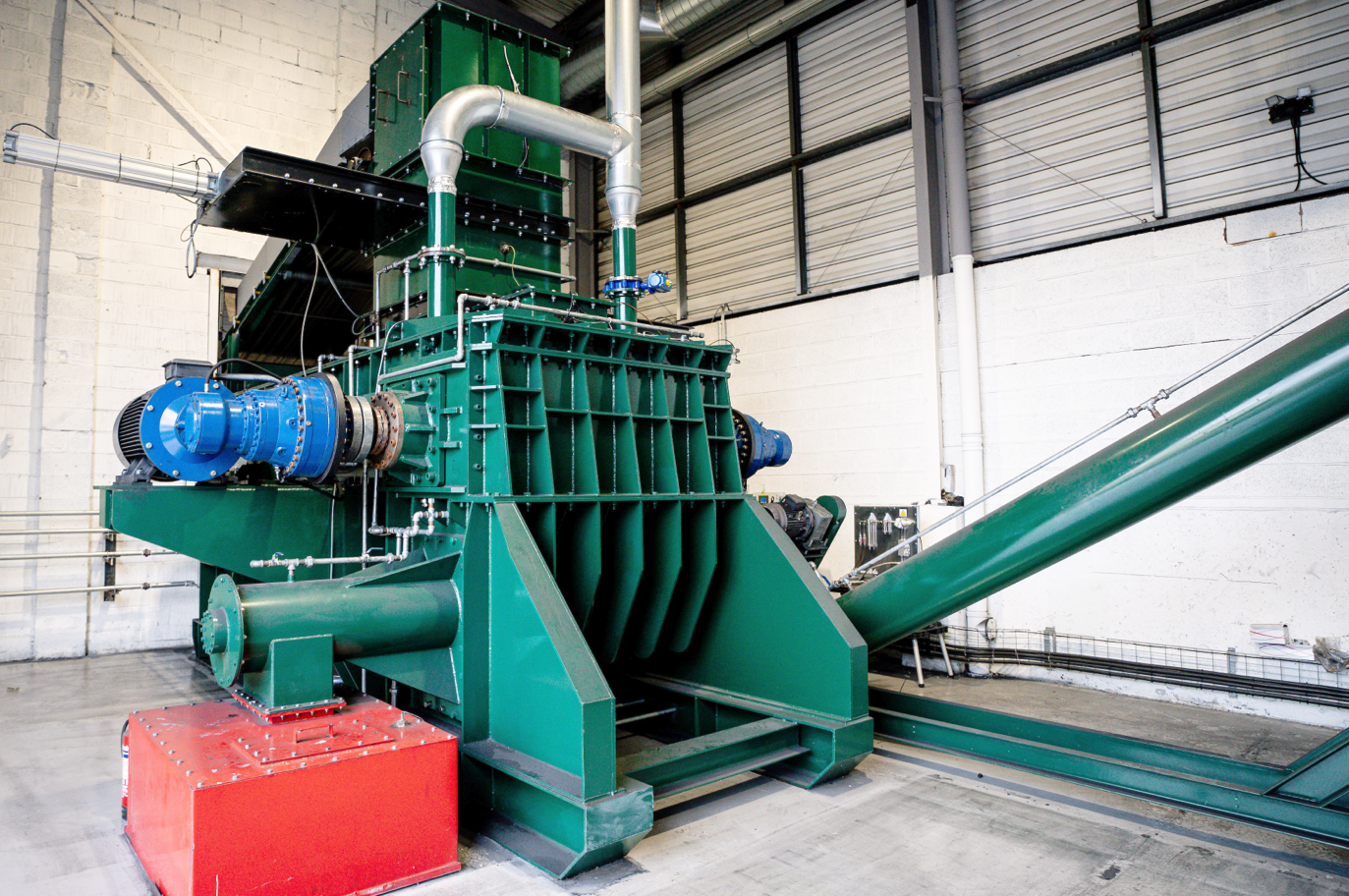

Industrial-Scale Lithium-Ion Recycling

Recyclus operates one of the UK’s first industrial-scale lithium-ion recycling facilities, capable of processing:

-

Medical mobility device batteries (wheelchairs, scooters, hoists)

-

Portable diagnostic and monitoring equipment batteries

-

Handheld tool batteries used by medical engineering teams

-

Digital health devices, tablets and specialist equipment

-

Backup and UPS lithium-ion systems for critical-care equipment

-

Batteries from decommissioned healthcare devices and equipment upgrades

Our process recovers:

-

Black mass rich in lithium, nickel, cobalt, and manganese

-

Copper, aluminium and other recoverable metals

-

Plastics and component materials for recycling

Healthcare clients receive full recycling certificates and environmental reporting for governance and sustainability requirements.

Fire Risk Reduction & Healthcare Safety Support

Lithium-ion batteries represent a growing fire hazard in clinical environments, particularly when damaged or improperly stored.

Recyclus helps healthcare providers mitigate these risks through:

-

Best-practice guidance for battery storage on wards, stores, and equipment

-

Emergency procedures for dealing with damaged or overheating batteries

-

Advice on compliance with healthcare waste, WEEE, and lithium-ion disposal regulations

This is particularly valuable in hospitals, community healthcare settings, pharmacies, and laboratories where equipment density is high.

How It Works

Healthcare Process Flow

1. Arrange Collection

Arrange Collection

2. Initial Inspection

Initial Inspection

3. Containment

Containment

4. Safe Dismantling

Safe Dismantling

5. Recycling & Recovery

Recycling & Recovery

6. Certifications & Reporting

Certifications & Reporting

5. Recycling & Recovery

Recycling & Recovery

6. Certifications & Reporting

Certifications & Reporting

Strategic Benefits for Healthcare Partners

Significant Reduction in Fire Risk

Reduced fire risk in clinical and equipment-storage environments

Compliance Assurance

Full compliance with healthcare waste regulations, WEEE directives, and battery-disposal laws

Secure Handling

Secure handling suitable for sensitive healthcare settings

Improved Governance

Improved governance through audit-ready documentation and traceability

Secure & Confidential Battery Handling for Sensitive Products

Recyclus provides specialised handling for confidential waste streams and next-generation product trials, ensuring security, discretion and full compliance at every stage.

Our facility is equipped to process:

-

Batteries from confiscated or restricted items, received through approved waste partners

-

Prototype, pre-production and next-generation devices from automotive, robotics, electronics and industrial sectors

-

Development batteries used in R&D labs, engineering teams and controlled testing programmes

-

Sensitive equipment requiring secure destruction, full audit trails and verified recycling outcomes

All confidential materials are managed under secure processes with:

-

Controlled access zones

-

Full chain-of-custody tracking

-

Secure destruction certificates

-

Non-disclosure aligned handling for sensitive technologies

This ensures high-risk or confidential battery waste — whether from law-enforcement seizures or cutting-edge engineering trials — is processed safely, discreetly and in full compliance with UK regulation.

Why Recyclus Group?

- Proven capability with damaged, swollen, and embedded lithium-ion cells

- Complete end-to-end handling: collection, stabilisation, and recycling

- Robust compliance, documentation, and traceability

-

-

We are the UK’s first industrial-scale lithium-ion battery recycler.

-

Our Wolverhampton facility is fully operational and processing large volumes of Li-ion batteries.

-

Extensive experience supporting regulated and safety-critical sectors

Find Your Bespoke Solution

Call Us

+44 (0) 1902 287561

Email Us

HQ Address

Lincoln Street,

Wolverhampton,

WV10 0DX