SECTORS

Robotics

We have already supported large-scale robotic deployments, including work with Ocado, recycling lithium-ion batteries from their advanced warehouse robots.

This experience demonstrates our capability to handle:

-

High-capacity robotic energy systems

-

Complex pack configurations

-

Strict operational security and confidentiality requirements

-

Large-volume and recurring recycling needs

Our robotics partnerships continue to expand across logistics, industrial automation, retail fulfilment, manufacturing and emerging autonomous systems.

Powering the future of automation — safely and sustainably

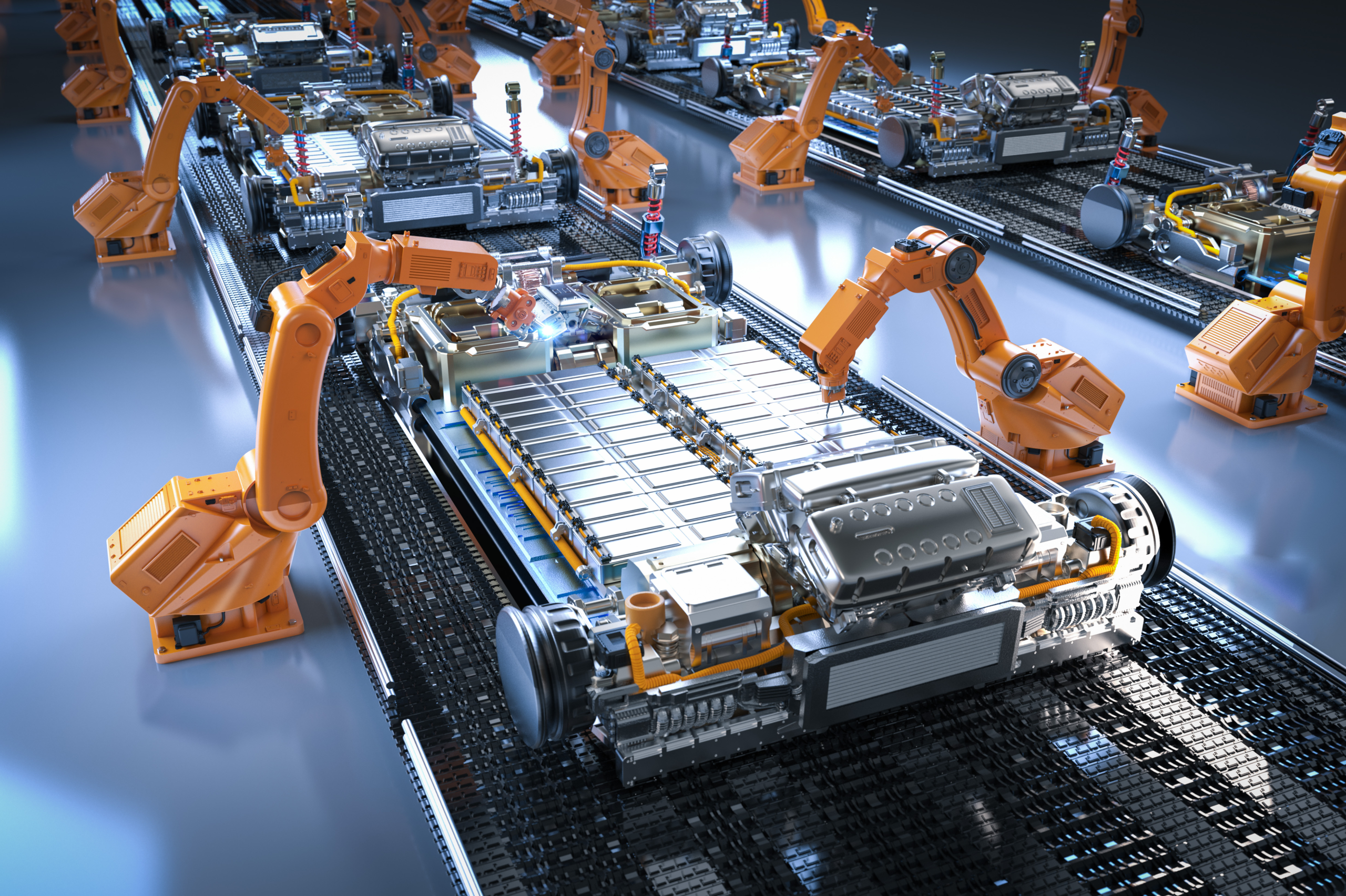

Robotics and automation depend on high-performance lithium-ion battery systems. Whether in warehouses, manufacturing, logistics, agriculture, inspection, AMRs, drones, cobots, or autonomous delivery fleets, reliable power is essential for efficient and uninterrupted operation.

As adoption accelerates, the robotics sector faces increasing pressure to manage:

-

High volumes of end-of-life and cycle-expired lithium-ion battery packs

-

Safety risks associated with ageing, swollen, damaged or high-energy packs

-

Compliance requirements for safe disposal and environmental management

-

The need for secure recycling pathways for proprietary or sensitive technology

-

Sustainability commitments across automated supply chains

Recyclus Group provides a specialist, UK-based end-to-end recycling solution designed for the demands of robotics and automation environments.

We have already supported major robotics deployments — including working with Ocado to recycle lithium-ion batteries from their automated warehouse robots — further strengthening our experience in handling complex, high-capacity robotic battery systems.

Our Robotics Services

Here’s how we support you end-to-end:

Safe Collection, Storage & Transport

We support robotics companies, automation integrators, engineering teams and logistics operators with:

-

ADR-compliant transport for large-format lithium-ion robot packs

-

Fire-safe, UN-certified “LiBox” containers that meet Packing Group I and ADR P911 regulations for warehouses, engineering workshops and robot charging hubs

-

Collection schedules aligned to maintenance cycles, fleet-refresh programmes or battery replacement intervals

-

Secure chain-of-custody documentation for proprietary or sensitive robotic equipment

This ensures your robot fleets remain safe, compliant and ready for continuous operation.

Battery Assessment, Dismantling & Pre-Treatment

Robotics batteries can be complex, proprietary, and built for high-duty cycles.

Recyclus provides:

-

Controlled dismantling of robotic battery packs, modules, and power systems

-

Depowering and neutralisation to remove thermal runaway risk

-

Sorting and classification by chemistry and condition

-

Safe handling for swollen, degraded, or physically damaged cells

-

Experience with warehouse robots, AGVs, AMRs, drones, and autonomous systems batteries

Our facility is built to manage both standardised robotic energy systems and custom-designed, high-capacity battery packs.

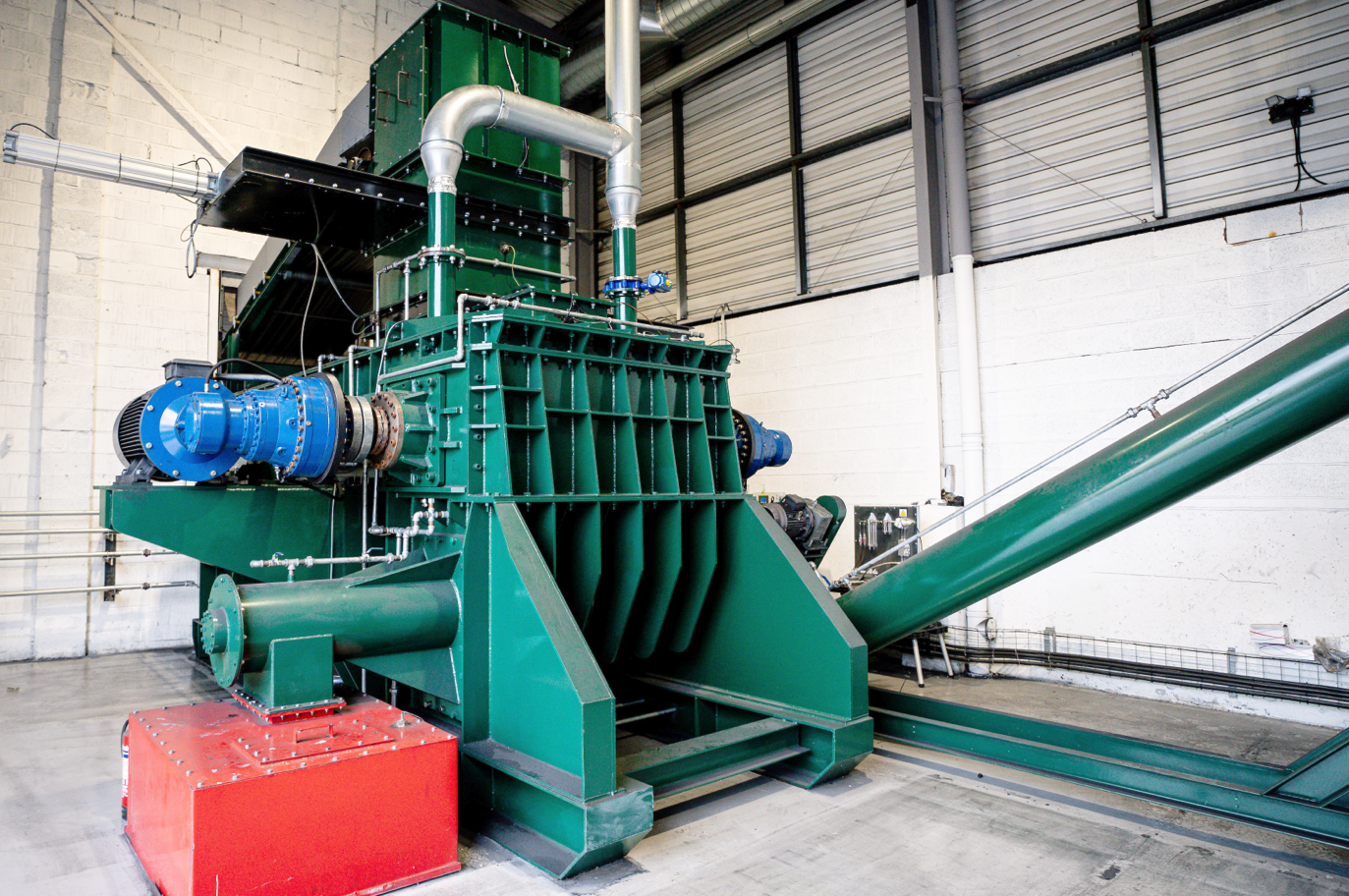

Industrial-Scale Lithium-Ion Recycling

Recyclus operates one of the UK’s first industrial-scale lithium-ion recycling lines, capable of processing:

-

Warehouse robot batteries (such as those used in automated fulfilment systems)

-

AMR and AGV Li-ion battery packs

-

Autonomous delivery robot batteries

-

Robotic arm and cobot power systems

-

Drone and inspection robot batteries

-

Robotics R&D and prototype power units

-

Backup and charging-station lithium packs

Our process recovers:

-

Black mass containing lithium, nickel, cobalt, and manganese.

-

Aluminium and copper fractions

-

Plastics and housings

We provide full certification, environmental reporting and secure documentation for each load.

Fire Risk Reduction & Healthcare Safety Support

Robotics environments — particularly warehouses and industrial automation sites — must minimise fire risk while maintaining uptime.

Recyclus supports robotics operators with:

-

Storage and segregation guidance for high-density lithium-ion battery systems

-

Emergency procedures for compromised or overheating packs

-

Advice on compliance with UK battery, WEEE, and hazardous-material regulations

This ensures robotics operations remain both efficient and safe.

How It Works

Robotics Process Flow

1. Arrange Collection

Arrange Collection

2. Initial Inspection

Initial Inspection

3. Containment

Containment

4. Safe Dismantling

Safe Dismantling

5. Recycling & Recovery

Recycling & Recovery

6. Certifications & Reporting

Certifications & Reporting

5. Recycling & Recovery

Recycling & Recovery

6. Certifications & Reporting

Certifications & Reporting

Strategic Benefits for Robotics Partners

Greater Operational Safety

Greater operational safety, reducing risks around high-energy batteries

Compliance Assurance

Full compliance with UK environmental and waste regulations

Proven Capability

Proven capability with complex and proprietary robotic battery systems

Sustainable and Circular Recycling

Sustainable and circular recycling, supporting carbon and ESG commitments

Secure & Confidential Battery Handling for Sensitive Products

Recyclus provides specialised handling for confidential waste streams and next-generation product trials, ensuring security, discretion and full compliance at every stage.

Our facility is equipped to process:

-

Batteries from confiscated or restricted items, received through approved waste partners

-

Prototype, pre-production and next-generation devices from automotive, robotics, electronics and industrial sectors

-

Development batteries used in R&D labs, engineering teams and controlled testing programmes

-

Sensitive equipment requiring secure destruction, full audit trails and verified recycling outcomes

All confidential materials are managed under secure processes with:

-

Controlled access zones

-

Full chain-of-custody tracking

-

Secure destruction certificates

-

Non-disclosure aligned handling for sensitive technologies

This ensures high-risk or confidential battery waste — whether from law-enforcement seizures or cutting-edge engineering trials — is processed safely, discreetly and in full compliance with UK regulation.

Why Recyclus Group?

- Proven capability with damaged, swollen, and embedded lithium-ion cells.

- Full end-to-end process: collection, dismantling, depowering, and material recovery.

- Robust compliance, documentation, and traceability.

-

-

We are the UK’s first industrial-scale lithium-ion battery recycler.

-

Our Wolverhampton facility is fully operational and processing large volumes of Li-ion batteries.

-

Strong track record supporting robotics and automation operators. Proven experience recycling batteries from major robotic fleets (including Ocado).

Find Your Bespoke Solution

Call Us

+44 (0) 1902 287561

Email Us

HQ Address

Lincoln Street,

Wolverhampton,

WV10 0DX