SECTORS

Automotive

Recyclus works with leading automotive partners to safely and sustainably recycle electric vehical lithium-ion batteries. Our process converts end-of-life packs into recoverable materials, including black mass, with full traceability and certification at every stage.

Why Choose Us?

At Recyclus, we understand that the move to electrification brings great opportunity — but also significant new responsibilities for vehicle manufacturers, dealers, repairers, and the wider motor trade.

-

The global surge in EV adoption means ever‐greater volumes of end-of-life or damaged high-voltage battery packs.

-

The risk of battery incidents (in particular thermal runaway and fires) is real and growing, especially in workshop, salvage, or storage environments.

-

Minimising downstream risk and integrating safe, circular‐economy practices is now a strategic imperative for OEMs and the motor trade alike.

With our UK-based industrial-scale facility, proprietary technology, full in-house capability, and a track record of handling complex, fire-damaged packs, we deliver a comprehensive service tailored for automotive clients.

Our Services for the Motor Trade

Here’s how we support you end-to-end:

Vehicle battery pack reception, storage & transport

-

We provide safe collection, handling, and transportation of high-voltage lithium-ion vehicle battery assemblies.

-

For damaged or compromised packs we offer specialist containment solutions (e.g., our UNP911-certified “LiBox” system) designed to reduce thermal-runaway risk on site or in transit.

-

Our logistics team works with you to ensure compliant ADR transport, proper documentation, and minimal disruption.

Specialist dismantling & pre-treatment

-

At our LiBatt facility, we dismantle EV battery packs — including those that have been subjected to thermal incidents — safely and efficiently.

-

Our high-voltage engineering team is experienced in handling batteries from leading OEMs, including fire-damaged packs. We convert them into safe intermediate components ready for recycling.

Recycling & resource recovery

-

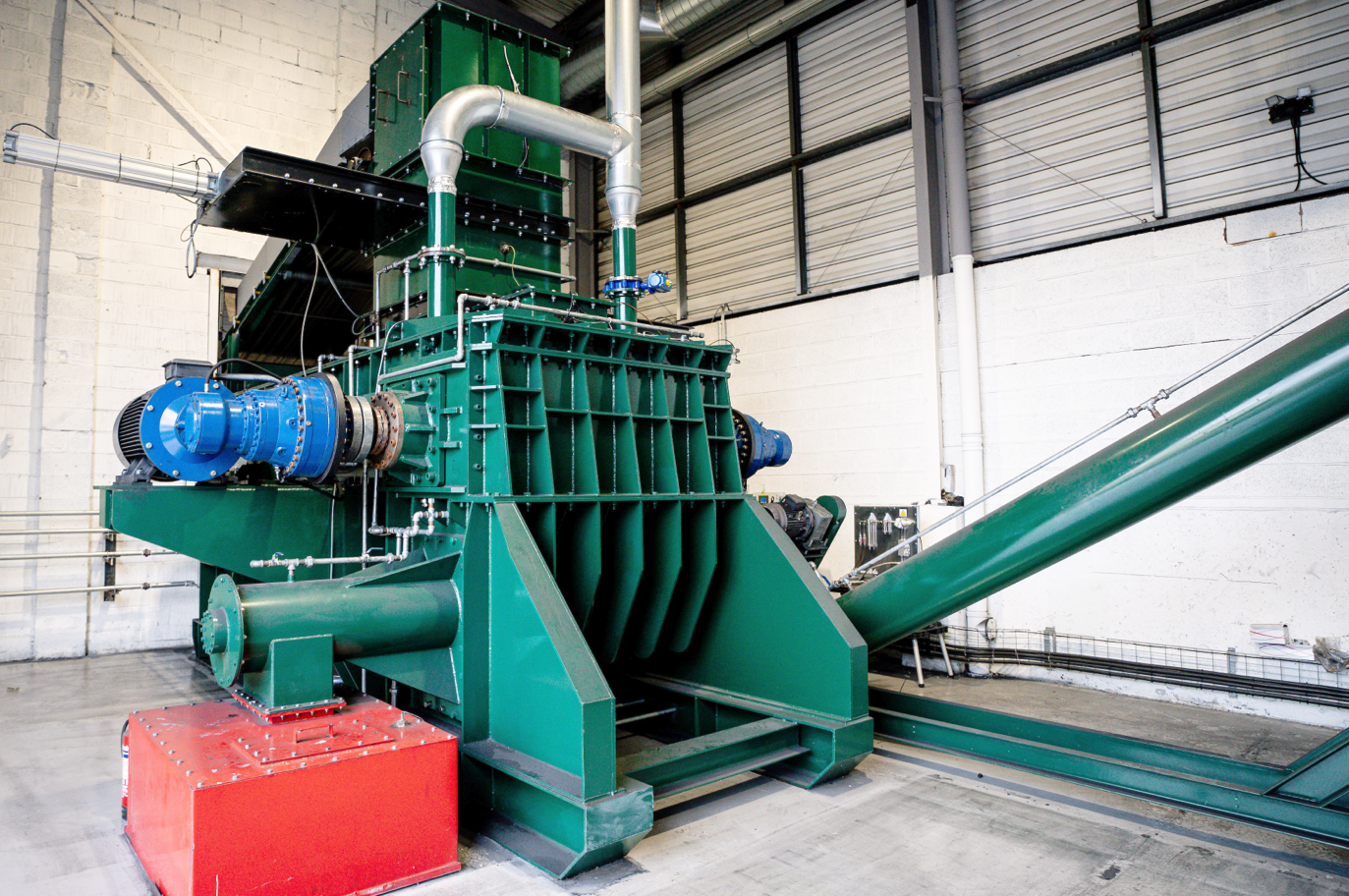

We operate an industrial-scale recycling process in Wolverhampton capable of processing large volumes of lithium-ion batteries across chemistries and vehicle types.

-

We extract “black mass” — a material rich in lithium, cobalt, nickel, and manganese — and reintroduce recovered materials into the supply chain, helping reduce dependency on raw extraction.

-

This supports OEMs and the motor trade in demonstrating circular-economy credentials and complying with evolving regulations.

Risk mitigation & consultancy

-

We support dealers, repair centres, and motor-trade operations in managing the specific fire and safety risks associated with lithium-ion battery handling.

-

By partnering with us, you gain access to best-practice protocols, safe containment systems, and a compliance-ready recycling partner.

-

Whether you’re managing in-house storage of defective EVs, awaiting inspection, or disposing of manufacturing scrap, we offer tailored advice and secure processing pathways.

How It Works

Automotive Process Flow

1. Arrange Collection

Arrange Collection

2. Initial Inspection

Initial Inspection

3. Containment

Containment

4. Safe Dismantling

Safe Dismantling

5. Recycling & Recovery

Recycling & Recovery

6. Certifications & Reporting

Certifications & Reporting

5. Recycling & Recovery

Recycling & Recovery

6. Certifications & Reporting

Certifications & Reporting

Why It Matters For Your Business

Compliance

With new regulatory pressure across Europe for vehicles, batteries and mobility, an end-of-life strategy isn’t optional.

Risk Reduction

Fires involving EV batteries can lead to multi-million-pound claims, particularly if stored or handled improperly.

Brand & Sustainability

Offering an end-to-end, safe and circular battery service supports OEMs, dealers and the motor trade in demonstrating responsible stewardship of electrified assets.

Cost Control

By creating a domestic UK solution (rather than exporting waste overseas) you reduce logistical complexity, carbon footprint, and supply-chain risk.

Secure & Confidential Battery Handling for Sensitive Products

Recyclus provides specialised handling for confidential waste streams and next-generation product trials, ensuring security, discretion and full compliance at every stage.

Our facility is equipped to process:

-

Batteries from confiscated or restricted items, received through approved waste partners

-

Prototype, pre-production and next-generation devices from automotive, robotics, electronics and industrial sectors

-

Development batteries used in R&D labs, engineering teams and controlled testing programmes

-

Sensitive equipment requiring secure destruction, full audit trails and verified recycling outcomes

All confidential materials are managed under secure processes with:

-

Controlled access zones

-

Full chain-of-custody tracking

-

Secure destruction certificates

-

Non-disclosure aligned handling for sensitive technologies

This ensures high-risk or confidential battery waste — whether from law-enforcement seizures or cutting-edge engineering trials — is processed safely, discreetly and in full compliance with UK regulation.

Why Recyclus Group?

- We offer tailored services for the motor trade — from safe storage/transport through to full recycling and material recovery.

- We provide full traceability, environmental credentials, and circular economy alignment.

-

-

We are the UK’s first industrial-scale lithium-ion battery recycler.

-

Our Wolverhampton facility is fully operational and processing large volumes of vehicle-battery and other lithium-ion sources.

-

We have experience with fire-compromised battery packs from leading automotive OEMs, showcasing our specialist capability.

Find Your Bespoke Solution

Call Us

+44 (0) 1902 287561

Email Us

HQ Address

Lincoln Street,

Wolverhampton,

WV10 0DX